product

factory Outlets for Fixed Gas Detection - DT-AEC2531 Combustible Gas Monitoring Device for Underground Well Room – Action

factory Outlets for Fixed Gas Detection - DT-AEC2531 Combustible Gas Monitoring Device for Underground Well Room – Action Detail:

Background

In the process of using natural gas detector, various equipment and devices such as pipelines, gate stations, pressure regulating equipment, valve wells, etc. are involved. These complicated gas supply equipment and pipe networks have brought many problems to the management of gas companies, especially the management of gas valve wells. Gas valve wells can cause gas leakage due to equipment aging, faults, and improper operation of personnel. However, traditional manual inspections are difficult to rush to the site for effective treatment in the first time due to the inspection density and inspection effect. All these have brought challenges to the management of gas companies.

Product advantages

1) Using advanced laser sensors (tunable laser spectroscopy (TDLAS) technology) with low false alarm and the service life is up to 5-10 years;

2) Adopt NB-IoT communication and cooperate with mainstream operators such as China mobile and telecommunications to ensure reliable communication;

3) The whole machine is designed with low power consumption and long working time, which can effectively reduce the equipment maintenance cost.

Main features

1) Large-capacity battery(152Ah) of domestic first-line brand, reliable capacity;

2) Using advanced laser sensors (tunable laser spectroscopy (TDLAS) technology, with high reliability, strong anti-interference ability, low false alarm rate and maintenance free;

3) Adopt NB-IOT wireless remote transmission solution, low power consumption, wide coverage and strong connection ability;

4) Well cover abnormal alarm and emergency treatment to prevent accidents;

5) The flooding alarm function detects the equipment status and informs the user that the equipment is in the detection empty window period.

Technical specifications

|

Performance |

|||

|

Detection principle |

Tunable diode laser absorption spectroscopy technology(TDLAS) |

||

|

Alarm error |

±3%LEL |

Detection range |

0 ~ 100%LEL |

|

Indication error |

±3%LEL(Displayed on the access platform) |

Alarm setting value |

Low limit:25%LEL; High limit:50%LEL |

|

Response time(T90) |

T90≤10s |

Wireless communication |

NB-IoT |

|

Detection interval |

60minutes(Standard working mode) |

Communication interval |

24hour(Standard working mode) |

|

Reporting time |

08:00(Default) |

Protection grage |

IP67 |

|

Explosion proof grade |

ExdibⅡCT4 Gb |

Sensor storage life (under normal storage environment) |

5 years |

|

Sensor service life (typical) |

5 years |

|

|

|

Electrical characteristic |

|||

|

Power supply |

Disposable lithium battery power supply(152Ah) |

Operating voltage |

3.6VDC |

|

Battery operating hours (under standard operating mode) |

≥3years |

Continue working time after battery under voltage (under standard working mode) |

15days |

|

Environmental parameters |

|||

|

Environmental pressure |

86kPa~106kPa |

Environment humidity |

≤100%RH(No condensation) |

|

Environment temperature |

-40℃~+70℃ |

Storage environment |

Storage temperature: -20℃~+30℃, relative humidity ≤60%RH, no corrosive substances on site |

|

Structure characteristics |

|||

|

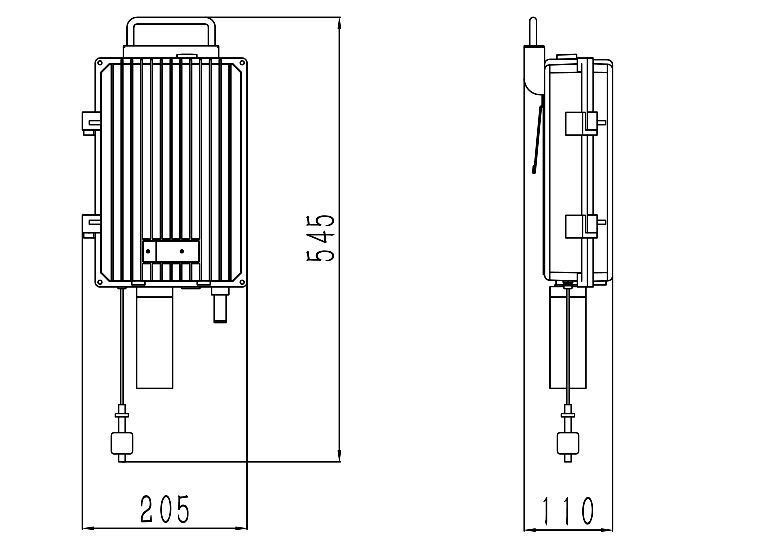

Dimensions |

545mm×205mm×110mm |

||

|

Material |

Cast aluminum |

||

|

Weight |

About 6kg(including battery) |

||

|

Installation mode |

Wall mounted: bracket hanging and fixing |

||

|

Stability |

100mm drop resistance (with packaging) |

||

Boundary Dimension

Mounting Mode

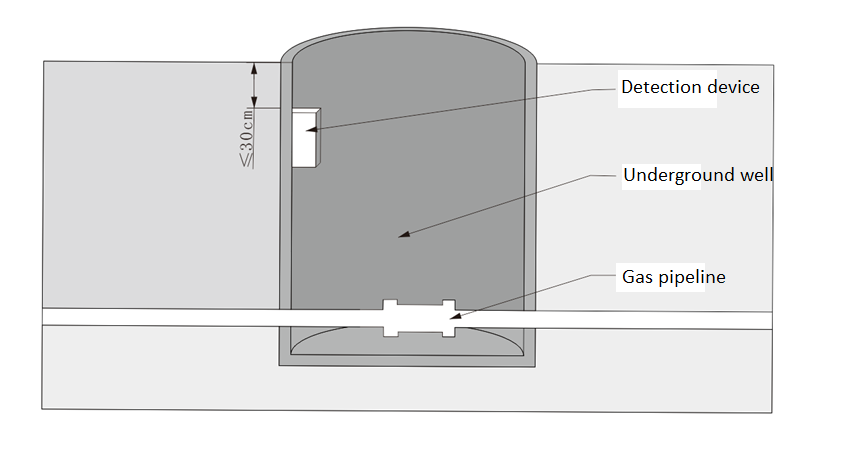

6.1 Detector installation mode:

When detecting combustible gas with lower specific weight than air such as methane, the detector shall be installed as close to the wellhead as possible (the distance from the wellhead shall not be more than 30cm)

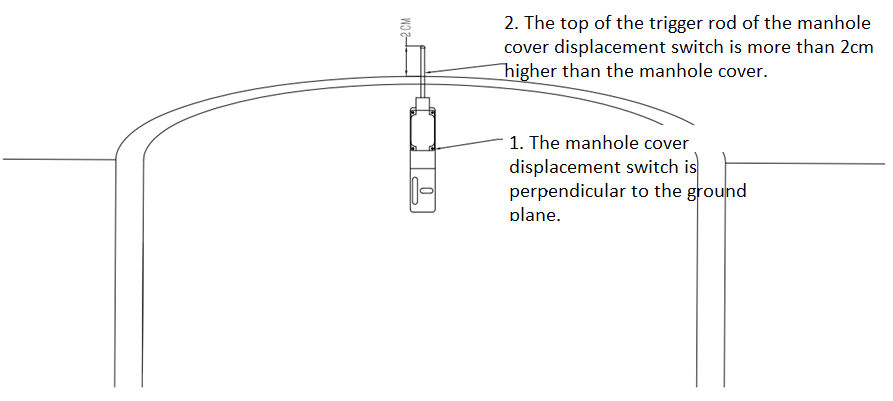

6.2 Manhole cover displacement switch installation method

The manhole cover displacement switch is perpendicular to the ground plane, and the top of the manhole cover displacement switch trigger rod is more than 2cm higher than the manhole cover (as shown in the figure below). After installation, the switch can be triggered when the manhole cover is closed.

Product detail pictures:

Related Product Guide:

We've got a really efficient group to deal with inquiries from prospects. Our purpose is "100% customer fulfillment by our product excellent, price & our group service" and enjoy a superb track record amid clientele. With many factories, we can easily deliver a wide selection of factory Outlets for Fixed Gas Detection - DT-AEC2531 Combustible Gas Monitoring Device for Underground Well Room – Action , The product will supply to all over the world, such as: Saudi Arabia, Irish, Malaysia, With the spirit of "credit first, development through innovation, sincere cooperation and joint growth", our company is striving to create a brilliant future with you, so as to become a most valuable platform for exporting our goods in China!

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.