product

OEM Supply Wifi Lpg Detector - GT-AEC2335 AC220V Powered Fixed Gas Detector – Action

OEM Supply Wifi Lpg Detector - GT-AEC2335 AC220V Powered Fixed Gas Detector – Action Detail:

Technical specifications

|

Item |

Data |

|

Principle of detection |

Catalytic combustion |

|

Sampling mode |

Diffusive sampling |

|

Detected range |

(0~100)%LEL |

|

Response time |

≤12s |

|

Operating voltage |

AC176V~AC264V (50Hz±1%) |

|

Power consumption |

≤4W |

|

Alarming mode |

Buzzer alarming and indicator alarming |

|

Protection grade |

IP66 |

|

Explosion proof grade |

ExdⅡCT6Gb |

|

Service life of the sensor |

Three years (typical) |

|

Environmental condition for operating |

Temperature: 0℃~+55℃; relative humidity: ≤93%; pressure: 86kPa~106kPa |

|

Storage temperature |

-20℃~+50℃ |

|

Outlet hole connecting thread |

NPT3/4"(female) |

Product Parameter Characteristics

| Detection principle | Catalytic combustion, Electrochemical | Signal transmission mode | A-BUS+、4-20mA、RS485 |

| Sampling mode | Diffusive sampling | Alarm error | ±3%LEL |

| Operating voltage | DC24V±6V | Indication error | ±3%LEL(display on the connected gas alarm controller) |

| Display mode | Digital tube display | Sound and light configuration | Optional ACTION explosion-proof audible and visual alarm |

| Power consumption | <3W(DC24V) | Signal transmission distance | ≤1500m(2.5mm2 ) |

| Press range | 86kPa~106kPa | Operating temperature | -40℃~+70℃ |

| Explosion proof grade | Catalytic combustion:ExdⅡCT6Gb/Ex tD A21 IP66 T85℃ (Explosion-proof + dust)Electrochemical:Ex d ib ⅡC T6 Gb/Ex t D ibD A21 IP66 T85℃(Explosion-proof + dust) | Humidity range | ≤93%RH |

| Shell material | Cast aluminum | Protection grade | IP66 |

| Electrical interface | NPT3/4"internal thread | ||

Major Features

● AEC220V power supply

This detector works while it is electrified (220V). The comprehensive cost is low. It has functions of controller + detector, as an independent system;

● Alarming mode

Audible-visual alarm: buzzer alarming and indicator alarming;

● Real-time concentration detection

Monitor combustible gases within the lower explosive limit in the industrial environment and give alarms;

● Linked output

Multiple output modes are available. The detector can link solenoid valves and fans, etc;

● Wireless transmission

GPRS communication modules are optional, used to send data to MSSP wirelessly. User can monitor equipment running statuses through a fixed terminal or a mobile terminal APP;

● High sensitivity

Automatic zero correction (to avoid zero wander that may cause a measurement error), automatic curve compensation, intelligent temperature and zero compensation algorithm (for better performance), low power consumption, two-point calibration, curve-fitting technique, high accuracy, stable performance and reliable sensitivity;

● IR remote control

An IR remote controller is used to set parameters;

● Application sites

Mini-sized industrial and commercial gas application sites in the urban fuel gas field.

Model Selection

|

Model |

Signal output |

Sensor equipped |

Adaptive control system |

|

GTY-AEC2335 |

NB-IoT or A-BUS+ bus signal GPRS wireless remote transmission DC12V capacity discharge + passive switching value For other output types, please consult with the head office |

Catalytic combustion |

Bus controller MSSP remote monitoring platform |

Model Selection

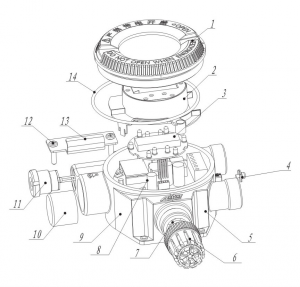

1. Top cover component

2. Plastic supporting cover

3. Circuit board -1

4. Grounding screw

5. Bottom box

6. Outer cover of the gas collecting head

7. Gas collecting head

8. Circuit board -2

9. Nameplate

10. Horn component

11. Switching button

12. Mounting screw

13. Mounting hook

14. Seal ring

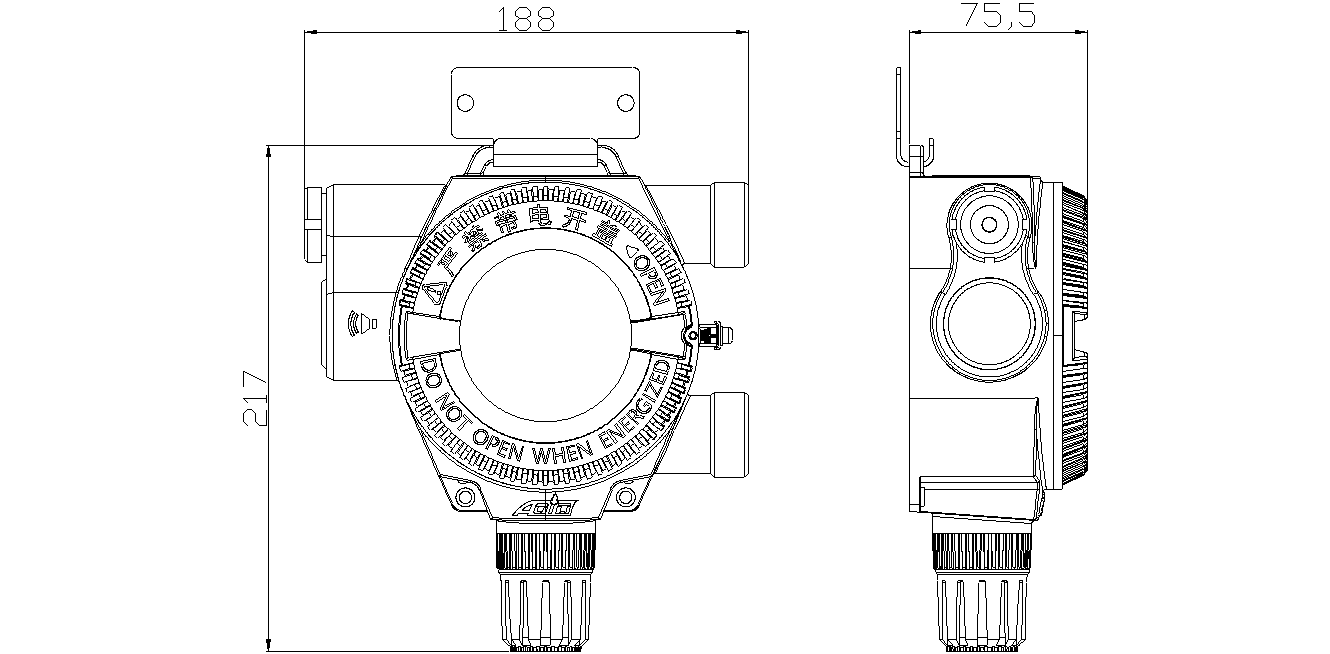

Boundary Dimension

Dimension: Length× width× height: 217mm×188mm×75.5mm

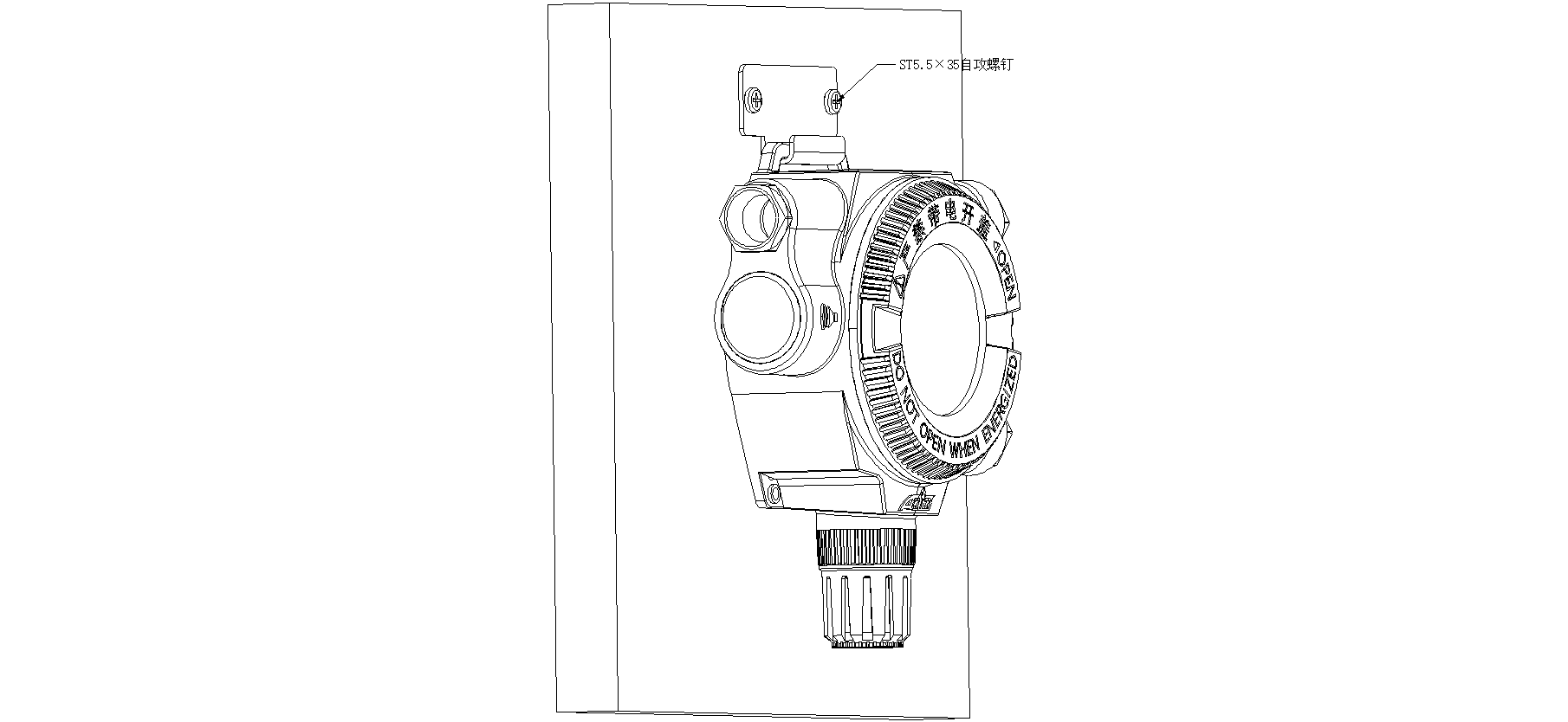

Mounting Mode

The detector should be wall-mounted. Please ensure that the detector is mounted firmly and reliably. The wall mounting mode is shown as below:

Product detail pictures:

Related Product Guide:

We keep on with the basic principle of "quality to start with, support very first, continuous improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the quality objective. To great our service, we offer the items with all the superior top quality at the reasonable selling price for OEM Supply Wifi Lpg Detector - GT-AEC2335 AC220V Powered Fixed Gas Detector – Action , The product will supply to all over the world, such as: Angola, Madrid, UK, Now we are sincerely consider to grant brand agent in different areas and our agents' maximum margin of profit is the most important thing we care about. Welcome all of the friends and customers to join us. We are ready to share win-win corporation.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!